Monday, December 31, 2007

Happy New Year to all RepRappers from "The land of the long, white cloud" aka Aotearoa, aka New

Zealand!

My Darwin (festooned in streamers by the girls) is in a compact state today, as I've been building a packing crate for it and checking the size a lot.

Vik :v)

Friday, December 21, 2007

Encapsulated Extruder Hopeless - Built New One

The previous extruder got trapped in a ball of PLA. The family wishes me to keep it as a memento and it looks fairly dicey to excavate so I've built a new one. Still no JB Weld about, so it's held together with BBQ paint again. I have learned through my mistakes though:

1. The thermistor is now mounted on a copper tag for easy removal.

2. The dome nut nozzle has been reshaped to a thinner point.

3. No insulation - it just absorbs plastic.

4. Heavy copper wires crimped to the nichrome heating coil.

5. Actually did wrap both ends of barrel in PTFE before assembly this time.

6. When drilling barrel using drill press, drill in half way from each end to keep hole central.

The first one I built had a pinhole leak in the barrel where my lousy drilling clipped the thread. I discover this after assembly. Moral: Check for leaks.

During testing I blew up 3 PICs. Moral: Insulate your thermistor leads well.

I also discovered that thermistors with a very low (<500 ohms) resistance at operating temperature spook the PIC's temperature measurement causing the heater to operate intermittently. If you've got one of these, stick a 560 ohm resistor in series with it and all should be well. You'll have to recalibrate of course. Moral: Try to use stock parts.

And now, she works again.

Vik :v)

1. The thermistor is now mounted on a copper tag for easy removal.

2. The dome nut nozzle has been reshaped to a thinner point.

3. No insulation - it just absorbs plastic.

4. Heavy copper wires crimped to the nichrome heating coil.

5. Actually did wrap both ends of barrel in PTFE before assembly this time.

6. When drilling barrel using drill press, drill in half way from each end to keep hole central.

The first one I built had a pinhole leak in the barrel where my lousy drilling clipped the thread. I discover this after assembly. Moral: Check for leaks.

During testing I blew up 3 PICs. Moral: Insulate your thermistor leads well.

I also discovered that thermistors with a very low (<500 ohms) resistance at operating temperature spook the PIC's temperature measurement causing the heater to operate intermittently. If you've got one of these, stick a 560 ohm resistor in series with it and all should be well. You'll have to recalibrate of course. Moral: Try to use stock parts.

And now, she works again.

Vik :v)

Wednesday, December 19, 2007

Experimental firmware working

I have now imported Andreas's improvements and corrections to the PIC firmware into Simon's experimental autoconf version of the code for the PIC16F648A. It all compiles, and - when put in a RepRap machine - works (at least it did for me...).

If you want to download it it's at

https://reprap.svn.sourceforge.net/svnroot/reprap/branches/autoconf-firmware

You should probably also look at Simon's instructions on the forum at:

http://forums.reprap.org/read.php?2,3861,3862

We need to do a bit more testing. Then if this all pans out OK this'll become the Subversion trunk version and we'll do a release.

The compiled .hex files (remember they're for a PIC16F648 or PIC16F648A, not a PIC16F628) can be downloaded from here. Unless you have more than one extruder on your RepRap, you can ignore the file extruder_1_.hex.

By putting this:

#define TESTLEN 53

static byte testArray[TESTLEN];

void init2()

{

testArray[TESTLEN-1] = 1;

...

in stepmotor2.c and increasing TESTLEN until the linker barfs I deduce that we have a whole 53 extra bytes to play with in the stepper code now!

If you want to download it it's at

https://reprap.svn.sourceforge.net/svnroot/reprap/branches/autoconf-firmware

You should probably also look at Simon's instructions on the forum at:

http://forums.reprap.org/read.php?2,3861,3862

We need to do a bit more testing. Then if this all pans out OK this'll become the Subversion trunk version and we'll do a release.

The compiled .hex files (remember they're for a PIC16F648 or PIC16F648A, not a PIC16F628) can be downloaded from here. Unless you have more than one extruder on your RepRap, you can ignore the file extruder_1_.hex.

By putting this:

#define TESTLEN 53

static byte testArray[TESTLEN];

void init2()

{

testArray[TESTLEN-1] = 1;

...

in stepmotor2.c and increasing TESTLEN until the linker barfs I deduce that we have a whole 53 extra bytes to play with in the stepper code now!

Tuesday, December 18, 2007

eMachined Extruder Parts

Recently, a cool dude by the name of Scott McClure emailed me about locating a supplier for machined parts. He mentioned a site called emachineshop.com which is really awesome. They have a free CAD application you can use to design parts to be made, get quotes, and order parts, all within the same application. I had heard of them before, but I didn't have a ton of experience with CAD so I didn't follow up.

Anyway, Scott suggested that we use them to get the machined parts we need for the extruder. Not only that, but he went above and beyond and made drawings up of the parts we need! He emailed me those files to look at, and hopefully have parts made from eventually.

The prices are reasonable at the quantities we're looking at, and the work that Scott did was very good. Here's the situation: it does not make sense to do a test order of a small number of parts, so we pretty much have to do a production size order. Obviously this runs the risk of getting 100 parts that are not what we need or want! I trust that the drawings Scott did are correct, but in the interest of perfection I present the files to you, the community to help spot any potential mistakes. Many eyes make bugs shallow, right?

Here are the files in question:

extruder drive screw - this is one piece with an extra 10mm of drilled shaft that is intended to be cut off by the end user to make the nut assembly to solder to the motor end of the braided wire.

half bearing - these are the bearings for the extruder drive screw.

heater barrel - this is the aluminum heater barrel for the extruder. (w/ 3/8"-16 threading)

ptfe barrel - this is the insulating PTFE thermal barrel. (w/ 3/8"-16 threading)

So please, download the emachineshop software, open the files above, check them out, and post any problems you find in the comments. This is really important, because a mistake could cost the RRRF hundreds of dollars (which at this point in the game, is a large amount)

Cheers,

Zach Smith

Anyway, Scott suggested that we use them to get the machined parts we need for the extruder. Not only that, but he went above and beyond and made drawings up of the parts we need! He emailed me those files to look at, and hopefully have parts made from eventually.

The prices are reasonable at the quantities we're looking at, and the work that Scott did was very good. Here's the situation: it does not make sense to do a test order of a small number of parts, so we pretty much have to do a production size order. Obviously this runs the risk of getting 100 parts that are not what we need or want! I trust that the drawings Scott did are correct, but in the interest of perfection I present the files to you, the community to help spot any potential mistakes. Many eyes make bugs shallow, right?

Here are the files in question:

extruder drive screw - this is one piece with an extra 10mm of drilled shaft that is intended to be cut off by the end user to make the nut assembly to solder to the motor end of the braided wire.

half bearing - these are the bearings for the extruder drive screw.

heater barrel - this is the aluminum heater barrel for the extruder. (w/ 3/8"-16 threading)

ptfe barrel - this is the insulating PTFE thermal barrel. (w/ 3/8"-16 threading)

So please, download the emachineshop software, open the files above, check them out, and post any problems you find in the comments. This is really important, because a mistake could cost the RRRF hundreds of dollars (which at this point in the game, is a large amount)

Cheers,

Zach Smith

Saturday, December 15, 2007

Print Head Auto-Encapsulation

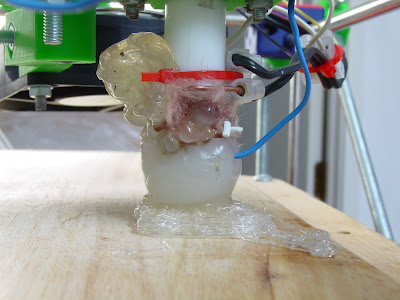

Millions of years ago, this prehistoric RepRap print head stumbled into a freshly emerging stream of molten PLA. It became trapped, the PLA smothered it, and it became completely encapsulated. Now this specimen is perfectly preserved, and industrial archaeologists can observe its primitive construction in minute detail. It may even be possible to extract early RepRap developer DNA.

Millions of years ago, this prehistoric RepRap print head stumbled into a freshly emerging stream of molten PLA. It became trapped, the PLA smothered it, and it became completely encapsulated. Now this specimen is perfectly preserved, and industrial archaeologists can observe its primitive construction in minute detail. It may even be possible to extract early RepRap developer DNA.This is going to be a complete bugger to chip free. I'll probably bake it at 150C for a while and pull all the crud off. The cable tie and terminal block will melt, of course. At least there is a thermocouple conveniently embedded in the blob. The girls, however, want me to preserve it as a memento so I may have to build a new one.

How the heck? I left the thing running overnight doing an X Axis Constraint and a serial error caused it to stall with the extruder motor and heater running.

Vik :v)

Thursday, December 13, 2007

Commit to SVN for nozzle-wipe method

I've committed a nozzle wipe method to the latest version of the software. This enables the nozzle to do a cleaning routine at the start/end of each layer. At the moment the cycle is as simple as can be (back and forth), but the structure's now in place for this to be developed. Here's some more parameters for your local properties file:

Extruder0_NozzleWipeEnabled=false

Extruder0_NozzleWipeFreq=4

Extruder0_NozzleWipeDatumY=12

Extruder0_NozzleWipeDatumX=20

Extruder0_NozzleWipeStroke=15

Extruder1_NozzleWipeEnabled=false

Extruder1_NozzleWipeDatumY=12

Extruder1_NozzleWipeDatumX=20

Extruder1_NozzleWipeStroke=15

Extruder1_NozzleWipeFreq=4

Extruder0_NozzleWipeEnabled=false

Extruder0_NozzleWipeFreq=4

Extruder0_NozzleWipeDatumY=12

Extruder0_NozzleWipeDatumX=20

Extruder0_NozzleWipeStroke=15

Extruder1_NozzleWipeEnabled=false

Extruder1_NozzleWipeDatumY=12

Extruder1_NozzleWipeDatumX=20

Extruder1_NozzleWipeStroke=15

Extruder1_NozzleWipeFreq=4

Tuesday, December 11, 2007

Wiping up

The nozzle oozes a bit for a few seconds after the extruder motor's been shut off. Naturally the dribble spoils the build a bit, so I thought I'd try building in a wiper to clean its noze before each layer. The framework comes off the diagonal, and looks a bit like an intergalactic spaceweapon. Things under test so far are razor blades and car windscreen wipers.

I'll keep you posted.

.jpg)

I'll keep you posted.

.jpg)

Monday, December 10, 2007

Half a step forward

I've corrected the PIC firmware so that it now correctly does half-stepping. It's checked back into the Sourceforge repository in Subversion.

This means that we can definitely use the cheaper 200-steps-per-rev stepper motors. You need a bipolar one where the coils can take a voltage of 12v and each use a current of 2A or less.

Details on the forums here.

This means that we can definitely use the cheaper 200-steps-per-rev stepper motors. You need a bipolar one where the coils can take a voltage of 12v and each use a current of 2A or less.

Details on the forums here.

Labels: firmware, stepper motor

Sunday, December 09, 2007

A Wet Weekend in Taupo

Not a bad weekend, actually. Participated into a project to build an impressive electric racing car (the Saker EV) in NZ, which meant attending a conference in Taupo for a couple of days. So, not much reprapping done, but I have at oh-dark-hundred managed to get the thing going like it was before I messed with it. I just changed too much at once without proving my new extruder barrel first.

So I'm now reprapping a V1.0 diagonal tie bracket, which is not very well shaped for single material printing. I've run one off anyway, just to test the machine while fixing up the corner bracket, and it's nearly finished. As it prints internal overhangs, it is creating this amazing "spaghetti-filled cavern" effect...

Hope to print a V1.1 and restart the changes more slowly by sticking in just the new X axis PIC.

Vik :v)

Friday, December 07, 2007

RepRappers: Unite!

Our esteemed colleague, Bruce Wattendorf has created an open google map for RepRappers to use to add their locations to. A few of us have already put our info up on the map, and if you're interested in proudly displaying your location you should too!

A day in the life of RepRap

Thought you guys might be interested... here's working day on RepRap @ the Bath University end:

Tuesday

Tuesday

Wednesday, December 05, 2007

Machinist Help Needed

The RRRF is looking for someone to make certain metal parts for the Extruder Kit. If you are that someone, you know that someone, or you're interested in submitting quotes to companies, please read the post and get back to me.

Ideally this will be someone in the USA because shipping costs make it impractical for the small number of items I need.

Thanks!

Ideally this will be someone in the USA because shipping costs make it impractical for the small number of items I need.

Thanks!