Saturday, March 31, 2007

ETech 2007

Adriaan tried to take pics of the presentation with his digital camera. Unfortunately, the hall was quite dark for the presentation which made his attempts dicey at best. This one is, however, my personal favourite.

I especially liked the vampire eyes thing. There were several business and technical media folks there. One American who writes for a Japanese business journal had much better digital camera equipment that we did and did extensive photography of the presentation. I'm hoping that I will be able to borrow a few of his pics for our archive.

I made the pitch for self-replicating printers, RepRap and Tommelise and we got good applause and very good questions in return. Afterward we had about a dozen of the people who'd attended stay over. Most of them had already been on both the RepRap and the Tommelise websites and one Brit there had even been down to Bath to meet Adrian.

There were people who were selling 3D printers, design engineers, product engineers and the lot. We've got a couple more product design firms that are probably going to be hammering for Darwins.

I also heard an excellent and interesting rationale for why a professional firm would want a self-replicating printer. It goes like this. They're paying $4.50/cubic inch for filament and if they don't use the filament that comes from the vendor they have their warrenty voided. They resent that a LOT.

As well, they'd like a printer that they could try different things with and fix if it broke. What we're working on fits that to a "T". As it is, the machines they have typically can only deal with one kind of plastic. The product design firms would like to do printing with a machine that wasn't a black box like the commercial machines.

One thing on the reprap site that really impressed the the people who are using commercial 3D printers was when both Vik and Adrian and Ed made shot glasses. You apparently can't make waterproof glasses on a stratasys. I heard about the tendency of stratasys prints to delaminate on the z-axis again, too.

Anyhow, the talk was well-received and O'Reilly was happy with it so we'll probably be asked again.

I noticed that several blogs had picked up on my talk. We got pretty good reviews.

Tuesday, March 27, 2007

Untimely Lapse Movie

Right at the end you can see the deposited part start to detach and go springy before it gets pushed around. You can also see the second head appearing in the right of the frame in the latter half of the movie. The camera moves around a little as the USB lead was dragging on things, but I fixed that with some tape about half way through; not a problem as it actually gave a better camera angle!

Adhesion to the stage (or lack thereof) is my big bugbear, and I'm going to try a light coat of varnish as previous tests have shown molten CAPA sticks to it like glue. If that doesn't work, I'm onto foam bases like the rest of 'em.

Vik :v)

Labels: bracket, capa, darwin, detached, fails, reprap, stage, zaphod

Monday, March 26, 2007

Darwin's X axis repeatability

Next on Darwin's todo list.. home sensors, wiring & documentation.

Labels: darwin, gear, performance, repeatability, reprap, x-axis

Sunday, March 25, 2007

Time-lapse video of test hexagon.

The object is a standard 20mm (approx) test hexagon, 5mm (quite accurate) thick, extruded from CAPA. There are approximately 2.5 seconds per frame. I used a Linux script of my own devising and a Logitech 320x240 webcam clamped to the base board, which I will document and GPL if anyone is interested. Donations of higher quality equipment greatfully accepted!

Here's what that lot looks like:

Vik :v)

Labels: capa, extrusion, fast, hexagon, polymorph, reprap, sped up, test, time lapse, video, zaphod

Friday, March 23, 2007

Bendy extruder gets things straight

I've done an alternative to the polymer extruder design that allows the 3mm diameter input filament to run straight down the drive screw without bending. This should allow us to use more brittle and stiffer materials in addition to CAPA. It should also make it easier to drop short lengths of filament down it from an automatic magazine at the side of the machine, for materials that can't be put on a long roll.

I drilled a 5mm-deep 3mm hole in the top of the M5 drive screw and soldered in a length of 3mm steel hawser that I bought at the local hardware shop. I had to grind/file down the hawser end a bit to get it to fit; I also added a little solder flux to get good surface wetting. It was important to be parsimonious with the solder, lest it soak up the wire and make it go rigid. On the other end I soldered another short piece of M5 studding, then soldered an M5 nut onto that.

I modified the motor mount to move it back from the line of travel of the filament being extruded, and made a small drive with an M5-nut-shaped hole.

Rather convieniently the predominant drive direction (anti-clockwise) tends to tighten the hawser coils, though the thing does drive perfectly well in both directions.

There's a video of the first mechanical test on the RepRap videos page.

Labels: new extruder design, stiff brittle extrudate

Friday, March 16, 2007

Darwin's X-axis toothed pulley

This was then complemented with Vik's superb idea of a washer + bit of capa for the second lip.

Next: a repeatabiltiy test for the X. Though I need to solder up a universal PCB first...

Labels: casting, darwin, gear, toothed pulley, x-axis

Darwin's Y-axis repeatability

Secondly and more importantly, the toothed pulleys from the previous post were put on the Y-axis. Big thanks to Adrian for sorting out the electronics and the repeatability programming!

Super glue was used to lock the little gears into position on the 8 mm drive bar. [Incorporating flats are on the development list]. The same repeatability test used on the Z-axis (see previous post) was re-used, results below:

After the first ten runs the repeatability appears to be in the ball park of ±0.04 mm. I think that the first few runs balance the tension: this is important because the transmission isn't symetrical:

It's worth stressing that this is not bad, we're still within our targets, but we need more data to pin down excatly what's going on. The next test will need 100+ runs.

Labels: darwin, performance, repeatability, y-axis

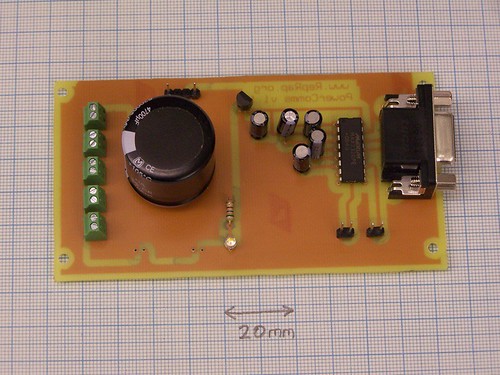

PowerComms v1.1: Success!

Adrian has successfully etched and soldered up one of the new one-sided Power / Communications boards for Darwin. Apparently it went really well, and I think he may even be picking up my vernacular. In his email he described it:

it's really sweet - whole thing took me 2 hours from cutting the bag round the virgin PCB to finishing testing (plus a 30 minute etching break when I ate supper). Tested out A OK first time

Updated instructions w/ the new pictures will be up on the wiki shortly.

Monday, March 12, 2007

Moulding thin walled gears, succeeds (!)

The final solution was to pack the capa into a former section wich held the teeth, mount that on a blade section with a ø8mm hole, hold the two concentrically in a pot and ram a file'd-up 8mm spike through the lot. Pre-packing the former guarantees the toothed impression, as does the angle of the spike, the blade nips off the excess, and the whole lot is easy to break apart after the capa's set.

After a bit of trimming, Bob's your uncle, as we say over here. (And, if your from the wrong part of over here, bob can also be your dad).

Friday, March 09, 2007

BBQ paint fails

I did a careful check and noticed as well that in places it was no longer stuck to the BBQ paint on the extruder barrel. While the heating coil was loose, it was not standing away from the barrel. I used only 175 mm of #32 nichrome 80 on this barrel in a single strand, so the loops in the coil are well away from each other.

Just to note I've had about 14 hours of hot operation on the this barrel to date. When I talk about "hot" operation, I'm talking about measured extruder barrel temperatures in the vicinity of 200-205 degrees C. I've had about the same number of hours of operation on my old test barrel which has been operated at about 140 degrees C. until very recently when I started trying to extrude ordinary solder. The BBQ on that one is still as good visually as the day I built it.

What that means is that if you use this approach with CAPA don't expect to encounter BBQ paint failure like I have.

Right now I'm in the process of putting another six coats of BBQ paint on the barrel to tack down the heating coil again. It's a sunny day out in my shady little patio where I'm doing that and that's going well.

Tuesday, March 06, 2007

Sebastien's polyethylene glycol

Sebastien mailed me a couple of kilos of polyethylene glycol. This is a water-soluble wax-like polymer that melts around 70oC. We have been thinking of using it as a support material.

I've been playing with it, and on its own it's much too fluid when molten - it has a viscosity similar to water. It thickens as it cools, but in order to get an extruded filament that way one would need far too fine a temperature control.

So I melted some and mixed it (2:3 by weight) with icing sugar. That makes a paste which is the ideal consistency. And it sets to a material that is like candle wax, but is water soluble (because both the sugar and the polyethylene glycol are).

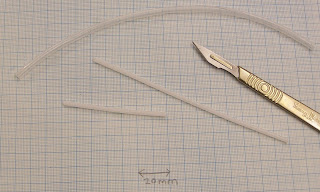

I used the same trick as I used the other day to make a 3mm rod of Wood's metal - squirting it from a syringe down a 3mm silicone tube, letting it freeze, then splitting that off with a scalpel. It's a bit brittle (as you can see its broken in two). This is good for support material removal, but for other tasks it would help if it was more flexible.

I tried miking it with glycerin as a plasticiser (medically, polyethylene glycol is often mixed with glycerin), but it seemed to react with the sugar to curdle and form lumps. This itself was interesting, but not quite what I wanted. so I'll see if I can find another compound that will make it more pliable. If I can do that it will definitely go through the standard extruder.

The Extruded Extruder Extrudes!

The extruded extruder is the one with the red light on. The black thing on the board is just to allow a bit of contrast so you can see the extruded stuff. I've used an ABS clamp off the Stratasys to hold the PTFE part of the nozzle, but I aim to replace that when the software is running happily again.

Zaphod now has two heads.

Vik :v)

Labels: capa, extruded, extruder, reprap, zaphod

Monday, March 05, 2007

Darwin makes a move

The motor torque was at 100%, speed 200 (see exerciser scale - approx 80%), and the results on the caliper bolted to the bed were... well... the graph can do the talking:

Happy days! I guess that puts the resolution at ±0.01 mm. There's still the X&Y to get moving yet, but it's good to know they're on solid foundations ;-)

Labels: darwin, performance, z-axis

Sunday, March 04, 2007

PowerComms Board v1.1

We've updated the design on the Power and Communications board. The parts are all the same, but now its a one sided board, and much easier to fabricate. All the files have been added to subversion, and the wiki entry will be updated with new pictures later this week once I actually make one.

In the meantime, here is a shot of the schematic from Kicad:

Changes

- single sided. makes it much easier to fabricate, and cheaper too. (no more alignment issues)

- fatter tracks on power circuits

- component silkscreen included for easier reference.

Labels: electronics, pcb, powercomms

CAPA vs. ABS bodies extruders

I've noticed that my half-washer bearings slip a bit (crappy job of smoothing the lands on the screw, I suspect), so I've packed a little bit of CAPA on top of them. This prevents exposed sharp edges engaging with the filament from dragging things around. In short, it stops your half-washers from popping out. I hope. Here's an old ABS one compared to the freshly-minted CAPA part. The CAPA part is the one on the left. The slightly fuzzy appearance of the bearing is due to Vaseline.

I've taken advantage of the squishy properties of CAPA a bit, I know, but it seems to work. Now we just hope the bearings don't heat up enough to melt the CAPA when you run them fast.

Keep on reading for our shameless fund-raising plug...

Vik :v)

Labels: bearing, capa, darwin, extruder, polymorph, reprap, washer