Saturday, August 05, 2006

A good start at slicing and dicing...

The VB.NET programme now does slicing, dicing and creating paths for the Mk II extruder to follow.

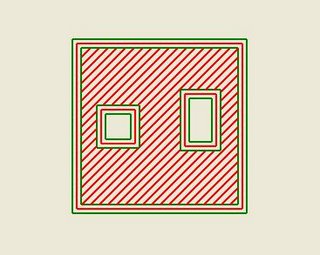

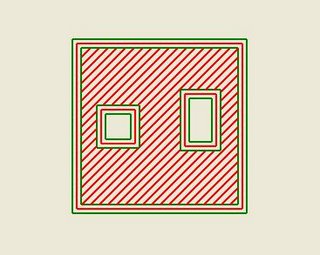

Here is a slice from a rectangle with two rectangular holes in it. The red lines represent the paths for the Mk II extruder.

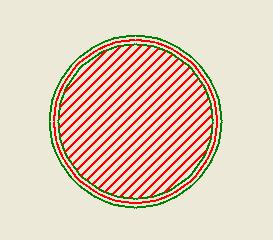

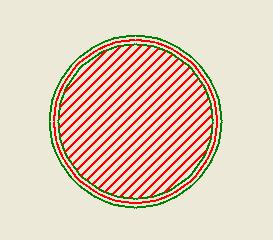

Similarly, here is a slice across a sphere for comparison. The green lines represent the outer boundaries of the perimeter extrusions. I've got to plowshare the infill paths to minimise the time the positioning stages require to do the extrusion.

The code at this point isn't very sophisticated, but it is a starting point and appears to be robust for the purposes at hand.

Now I have to decide whether I want to do something else for a change or tackle the problem of doing support structures. I'm thinking that there is a sneaky way of skinning that particular cat. :-)

Here is a slice from a rectangle with two rectangular holes in it. The red lines represent the paths for the Mk II extruder.

Similarly, here is a slice across a sphere for comparison. The green lines represent the outer boundaries of the perimeter extrusions. I've got to plowshare the infill paths to minimise the time the positioning stages require to do the extrusion.

The code at this point isn't very sophisticated, but it is a starting point and appears to be robust for the purposes at hand.

Now I have to decide whether I want to do something else for a change or tackle the problem of doing support structures. I'm thinking that there is a sneaky way of skinning that particular cat. :-)

Comments:

<< Home

Moving right along there! So how do you think you'll link up those fill lines? I suppose it gets a bit odd when you have a hole in the object, or worst, two. Not that I'm expecting that to slow you down much. LOL

BTW, got a couple of introductory books, one on electronics, and the other on digital electronics. Lets hope Neanderthal can evolve a bit more. :)

BTW, got a couple of introductory books, one on electronics, and the other on digital electronics. Lets hope Neanderthal can evolve a bit more. :)

***So how do you think you'll link up those fill lines?***

Why should I want to do that? I'm designing the positioning stages to move at 20-30 mm/sec. Doing sharp changes in direction while extruding isn't something I want to do unless I absolutely have to, like when I'm doing the perimeters. Trying to do continuous extrusions is really slow.

Why should I want to do that? I'm designing the positioning stages to move at 20-30 mm/sec. Doing sharp changes in direction while extruding isn't something I want to do unless I absolutely have to, like when I'm doing the perimeters. Trying to do continuous extrusions is really slow.

Oh, I see, so your machine will just lay fill in a back and forth motion, extruding over the shape, only changing paths when it is not extruding?

Not sure why continuous extrusion is really slow...

Not sure why continuous extrusion is really slow...

My Frankenmotors are as big as my fist. There is a lot of intertia there when I need to change speeds that I have to overcome. I either go real slow to minimise the effect of intertia or put a lot of stress on the motors and the structure of Godzilla.

Post a Comment

<< Home