Sunday, July 13, 2008

New Board: Magnetic Rotary Encoder v1.0

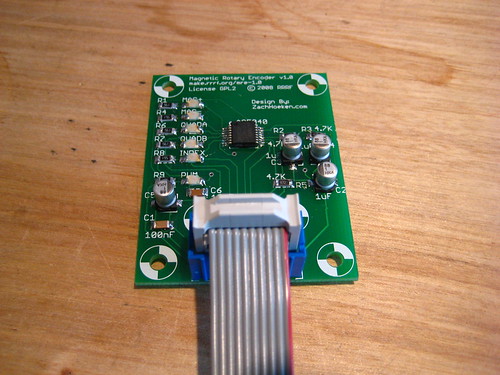

I'm very proud to announce a new board, designed and developed by the RepRap Research Foundation. Its called the Magnetic Rotary Encoder, and it uses a magnet to provide positional feedback information. It is based around the AS5040 chip, and provides 10-bits of resolution per rotation (1024 different positions!) It has 5 different output modes, a 6.1mm hole that fits the magnet for easy aligning, plenty of diagnostic LEDs for coolness, and 6 different mounting holes for ease of use, including GM3 gearmotor mounting holes.

I'm very proud to announce a new board, designed and developed by the RepRap Research Foundation. Its called the Magnetic Rotary Encoder, and it uses a magnet to provide positional feedback information. It is based around the AS5040 chip, and provides 10-bits of resolution per rotation (1024 different positions!) It has 5 different output modes, a 6.1mm hole that fits the magnet for easy aligning, plenty of diagnostic LEDs for coolness, and 6 different mounting holes for ease of use, including GM3 gearmotor mounting holes.Rotary encoding is one of the major innovations that Nophead uses in his extrusion process that has led to such high quality prints. Now, we have a standard, open source design that is intended for use with the GM3 gearmotor that we use on our extruder.

We have full documentation available on our wiki, an experimental GCode firmware for Arduino with support for it, and you can even buy a kit from the RRRF online store.

Comments:

<< Home

Awesome Zach! I just hacked a PS2 mouse encoder onto my GM3, but I'm only getting 6 bits per revolution. The real problem is the update rate though - it's nice having the debouncing done for me by the mouse microcontroller, but the conversion to 5V rs232 and back means I get the updates a little later than I'd like.

Sign me up for a kit!

Sign me up for a kit!

thanks guys!

forrest: there is a SMT tutorial linked in the instructions, but its actually pretty simple. the main technique is not to worry about bridges (too much). after you solder the chip down, you take some desoldering wick to it and suck up any bridges. bingo... perfect SMT chip =)

forrest: there is a SMT tutorial linked in the instructions, but its actually pretty simple. the main technique is not to worry about bridges (too much). after you solder the chip down, you take some desoldering wick to it and suck up any bridges. bingo... perfect SMT chip =)

Sweet! So that actually works. It's one thing to read about it and quite another to have someone you actually know manage it.

Where did you get your soldering paste, if I may ask?

Where did you get your soldering paste, if I may ask?

forrest: no soldering paste used. i just used some thin solder (.020 i think?)

these boards have solder mask between the traces which *really* helps keep the solder where you want it.

this was my first SMT board i've ever soldered. i was really nervous when soldering it, but afterwards i was both blown away with how easy it was and also slightly embarrassed that i was intimidated by a SMT part.

these boards have solder mask between the traces which *really* helps keep the solder where you want it.

this was my first SMT board i've ever soldered. i was really nervous when soldering it, but afterwards i was both blown away with how easy it was and also slightly embarrassed that i was intimidated by a SMT part.

I've got a few RC servos lying around (up to 15 kg.cm stall torque, cost about AU$10 each), and I'm wondering whether I could use them in place of the GM3. Would need to mod them so they are not limited to 120º rotation, but that's not a big deal.

Can anyone see any potential problems with using RC servos in conjunction with the Magnetic encoder? it would remove the need for dc motor controllers, as the servos take PWM signals directly.

Post a Comment

Can anyone see any potential problems with using RC servos in conjunction with the Magnetic encoder? it would remove the need for dc motor controllers, as the servos take PWM signals directly.

<< Home