Tuesday, May 16, 2006

Support material conclusions

Hi, so my (James Low's) final year project under the supervision of Adrian involved investigating and proposing an alternative, low-cost support structure material for the RepRap FDM process and the means of its automated deposition. So here are my findings.

Having had icing sugar proposed to me as an idea I quickly found that it was unable to be deposited at 0.5mm resolution and that it took a long time to set (over 1hour).

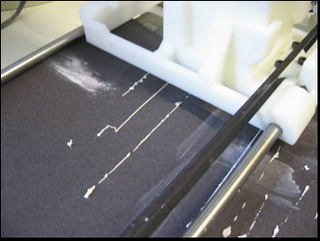

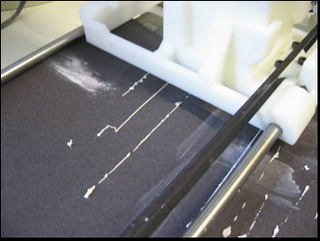

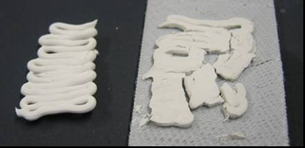

However, Polyfiller was the perfect substance. I was able to deposit Polycell Fine Surface Polyfiller from a 0.5mm nozzle, creating a perfectly consistent line, which set hard within 2 minutes.

An initial problem was that Polyfiller, once set, would not fully remove from the surface of an ABS part(although it would remove from the syringe nozzle if placed in warm, soapy water within an hour or so of exposure). But Adrian's use of vegetable oil as a releasing agent on the ABS cude (Blogged in April 2005) resulted in using it (veg oil) to see if it would aid Polyfiller's removal from ABS parts, which it did perfectly.

An initial problem was that Polyfiller, once set, would not fully remove from the surface of an ABS part(although it would remove from the syringe nozzle if placed in warm, soapy water within an hour or so of exposure). But Adrian's use of vegetable oil as a releasing agent on the ABS cude (Blogged in April 2005) resulted in using it (veg oil) to see if it would aid Polyfiller's removal from ABS parts, which it did perfectly.

ABS part (previously coated in veg oil) covered in Polyfiller.

ABS part (previously coated in veg oil) covered in Polyfiller.

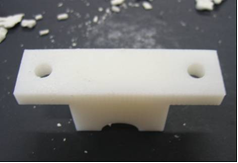

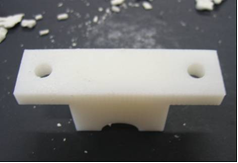

The same part after the Polyfiller had been removed.

The same part after the Polyfiller had been removed.

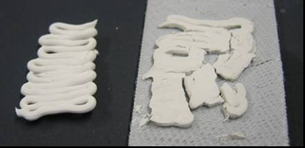

The vegetable oil was deposited as a thin layer using a brush, and it was also possible to separate Polyfiller layers from themselves. It could be best to deposit the oil from a felt tip pen, replacing the ink with oil, which could then be simply deposited as a thin layer in the FDM process.

Ignore the cracked layer (it was cracked before the layers were separated).

The pictures and information regarding the deposition mechanism for the Polyfiller will be added soon (next few hours).

Having had icing sugar proposed to me as an idea I quickly found that it was unable to be deposited at 0.5mm resolution and that it took a long time to set (over 1hour).

However, Polyfiller was the perfect substance. I was able to deposit Polycell Fine Surface Polyfiller from a 0.5mm nozzle, creating a perfectly consistent line, which set hard within 2 minutes.

An initial problem was that Polyfiller, once set, would not fully remove from the surface of an ABS part(although it would remove from the syringe nozzle if placed in warm, soapy water within an hour or so of exposure). But Adrian's use of vegetable oil as a releasing agent on the ABS cude (Blogged in April 2005) resulted in using it (veg oil) to see if it would aid Polyfiller's removal from ABS parts, which it did perfectly.

An initial problem was that Polyfiller, once set, would not fully remove from the surface of an ABS part(although it would remove from the syringe nozzle if placed in warm, soapy water within an hour or so of exposure). But Adrian's use of vegetable oil as a releasing agent on the ABS cude (Blogged in April 2005) resulted in using it (veg oil) to see if it would aid Polyfiller's removal from ABS parts, which it did perfectly. ABS part (previously coated in veg oil) covered in Polyfiller.

ABS part (previously coated in veg oil) covered in Polyfiller. The same part after the Polyfiller had been removed.

The same part after the Polyfiller had been removed.The vegetable oil was deposited as a thin layer using a brush, and it was also possible to separate Polyfiller layers from themselves. It could be best to deposit the oil from a felt tip pen, replacing the ink with oil, which could then be simply deposited as a thin layer in the FDM process.

Ignore the cracked layer (it was cracked before the layers were separated).

The pictures and information regarding the deposition mechanism for the Polyfiller will be added soon (next few hours).

Comments:

<< Home

Polyfiller! Now there's a name that brings back memories. I must have used a truckload of that stuff patching the cement plaster of my old house in South Africa! :-D

Good job James!

Good job James!

Yup, looks like a good one. I'm going to have a think on how to fix that to an overhead rail for fixed-head designs.

Vik :v)

Vik :v)

Just a thought, James - does mixing sugar or corn syrup in the Polyfiller make it easier to remove? It works with cement.

Vik :v)

Vik :v)

I forsee a potential problem - how would you remove the polyfiller from a concave cavity in a component? Even if it wasn't stuck to the surfaces, it would be trapped by the geometry. Is there any way of dissolving it without also damaging the component?

I think Tom meant from a cavity in the part it is making. The way we'll solve that, I think, is to lay the stuff down in an open pattern so that it supports, but has air gaps and crumbles easily.

Post a Comment

<< Home