Tuesday, May 16, 2006

Gear reduction...

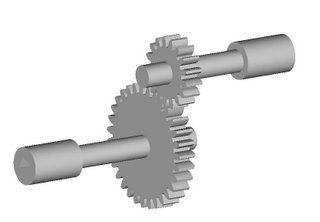

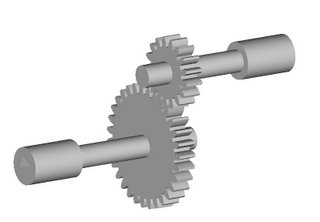

After thinking about it for a while, I bought five of these to see if I can go at it more efficiently from high rpm to low. The MECI people had a 20% off sale on this month so I got 'em for US$4.76/unit.

After thinking about it for a while, I bought five of these to see if I can go at it more efficiently from high rpm to low. The MECI people had a 20% off sale on this month so I got 'em for US$4.76/unit.That 1.8:1 reduction should make for a lot less hours on the Stratasys. :-)

A 31:17 toothed gear train for it looks quite reasonable.

Comments:

<< Home

I have been following the progress on the RepRap 'blog, and noticed you having problems with the torque/speed relationship of the stepper motors. I too had similar problems when driving steppers in a robotics application, and I discovered the solution on the following website: Oatley Electronics CNC Machines

The key seems to be driving the motors with a constant-current source, rather than the more usual constant voltage source. In this way, as the torque (current) drops off at higher speeds, the power supply increases the voltage, maintaining the motors torque at the higher speeds. I was able to get motors of a similar size and step-resoltion to what you're using, humming along quite fast (60-70cm/sec) for a tracked robot, instead of the paltry 5-10cm/sec I could get with simple voltage drive.

Overall I think you have given up too quickly on the stepper motors, they are a far better proposition for a machine like yours than a simple DC gearmotor.

Regards,

Cary

The key seems to be driving the motors with a constant-current source, rather than the more usual constant voltage source. In this way, as the torque (current) drops off at higher speeds, the power supply increases the voltage, maintaining the motors torque at the higher speeds. I was able to get motors of a similar size and step-resoltion to what you're using, humming along quite fast (60-70cm/sec) for a tracked robot, instead of the paltry 5-10cm/sec I could get with simple voltage drive.

Overall I think you have given up too quickly on the stepper motors, they are a far better proposition for a machine like yours than a simple DC gearmotor.

Regards,

Cary

Thanks cary, that's very kind of you. I'm going to pass what you've said and the link around to the rest of the team.

Just seconding cary's comments. I'm no expert but have been looking into related aproaches. Seems geared DC motors are not as simple a solution as one might think...

I've been reading up on constant current drive designs and I think I know how it was that this approach was not followed.

If I got what I read right you have to have a rather high voltage DC source, ca about 24-36 volts to make the scheme work. We had, early on, fixed on 12 volt current because of the 3rd world focus of the prototyper in that common automotive lead-acid batteries are rated at 12 volts. As well, cheap power supplies from PC's are another very cheap source of 12v DC power.

That's probably why it hasn't been considered in the past.

If I got what I read right you have to have a rather high voltage DC source, ca about 24-36 volts to make the scheme work. We had, early on, fixed on 12 volt current because of the 3rd world focus of the prototyper in that common automotive lead-acid batteries are rated at 12 volts. As well, cheap power supplies from PC's are another very cheap source of 12v DC power.

That's probably why it hasn't been considered in the past.

"We had, early on, fixed on 12 volt current because of the 3rd world focus of the prototyper..."

Certainly a good cause.

I've spent months working in an environment without grid electricity, this is a complex issue! In my experiance, powering anything off a car battery for more than a few moments is a substantial undertaking. I mostly turned to investigating steam power and the pneumatic side of robotics. LOL! Also, my focus quickly moved to the much more fundamental problem of electrical generation/supply, rather than things that consume it.

I would suggest that anyone capable of building a reprap machine is clever enough to have provided themselves with 240 or 120v AC through generator, solar or wind power, and/or has built up a -large- array of semi-retired 12v auto batteries which could supply much more than 12 volts.

Maybe working off a 12v battery is something future generations of repraps could evolve down towards?

Post a Comment

Certainly a good cause.

I've spent months working in an environment without grid electricity, this is a complex issue! In my experiance, powering anything off a car battery for more than a few moments is a substantial undertaking. I mostly turned to investigating steam power and the pneumatic side of robotics. LOL! Also, my focus quickly moved to the much more fundamental problem of electrical generation/supply, rather than things that consume it.

I would suggest that anyone capable of building a reprap machine is clever enough to have provided themselves with 240 or 120v AC through generator, solar or wind power, and/or has built up a -large- array of semi-retired 12v auto batteries which could supply much more than 12 volts.

Maybe working off a 12v battery is something future generations of repraps could evolve down towards?

<< Home