Friday, January 06, 2006

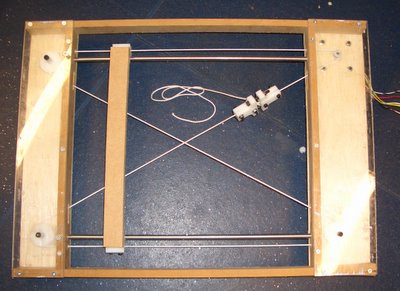

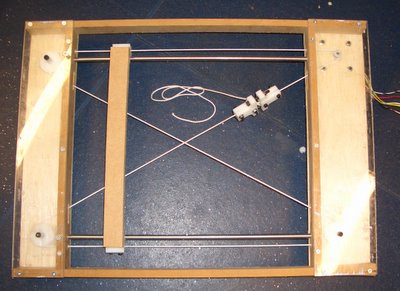

Pulley accuracy test rig

Here's the test rig I'm using to see how accurate a pulley transmission will be. The string is para-cord ø 2mm (nylon?). After putting this on the force tester, strain and creep factors were surprisingly high. Although it will just about do for the time being, I'll need better performance for Mk 2. Am thinking insulated electrical wire is a useful resource here?

Results on the nylon cord will follow next week.

eD

Comments:

<< Home

Ed, you may want to use the cable rigging convention that the old parallel bars on drafting tables use. It avoids the need for the crossed cables under your work surface.

It looks like this...

www.sanma12.com/Forrest/cable_for_parallel_bar.jpg

It looks like this...

www.sanma12.com/Forrest/cable_for_parallel_bar.jpg

I think I read somewhere that kevlar string is quite strong and inelastic.

I found this in an article about building a

string tensioned telescope:

I looked and looked for Kevlar string, because of it's low stretch characteristics. All of the Kevlar string I found was braided. Even though the Kevlar strands don't stretch, the braid tightens up, and the overall string does stretch. Someone on the ATM list suggested that I try an archery shop. I found a string with the brand name of Spectra. It has separate strands that are not braided, with a cloth outer jacket, and it has very little stretch. This string works well as is, but I was able to take the core (the fiberglass) out of the jacket, double it, and put it back in the jacket, making it have half as much stretch.

I found this in an article about building a

string tensioned telescope:

I looked and looked for Kevlar string, because of it's low stretch characteristics. All of the Kevlar string I found was braided. Even though the Kevlar strands don't stretch, the braid tightens up, and the overall string does stretch. Someone on the ATM list suggested that I try an archery shop. I found a string with the brand name of Spectra. It has separate strands that are not braided, with a cloth outer jacket, and it has very little stretch. This string works well as is, but I was able to take the core (the fiberglass) out of the jacket, double it, and put it back in the jacket, making it have half as much stretch.

Ah, the material of choice is Dacron B50. I use it for bowstrings (Adrian might take note :). Doesn't stretch much and is tough as old boot.

Ed, you might want to take a look inside a flat-bed scanner and see how they arrange their cables to make the bar light and scanner head go back and forth.

Vik :v)

Ed, you might want to take a look inside a flat-bed scanner and see how they arrange their cables to make the bar light and scanner head go back and forth.

Vik :v)

Ah, a fellow archery enthusiast!

This problem of stopping cables from stretching is the chief reason I try to avoid such mechanisms as much as possible - when I do use them, I personally prefer steel cable.

Another, more long-term problem is that relying on specialist cables, such as high-end bowstrings, decreases the ease with which the machine can be constructed and distributed - I doubt there are many specialist archery shops in some third world countries where the reprap technology might eventually spread. Linkages like the peaucellier or sarrus have the advantage that they could be entirely made by another fabricator using base materials, though I suppose one could use a fabricator to manufacture a specialist string-making machine and then manufacture the bowstring using that....

This problem of stopping cables from stretching is the chief reason I try to avoid such mechanisms as much as possible - when I do use them, I personally prefer steel cable.

Another, more long-term problem is that relying on specialist cables, such as high-end bowstrings, decreases the ease with which the machine can be constructed and distributed - I doubt there are many specialist archery shops in some third world countries where the reprap technology might eventually spread. Linkages like the peaucellier or sarrus have the advantage that they could be entirely made by another fabricator using base materials, though I suppose one could use a fabricator to manufacture a specialist string-making machine and then manufacture the bowstring using that....

That's why I'm seriously exploring the option of using a Stewart platform. The control is more complex, and it takes more motors, but they're very rigid for a given amount of structure. And you could switch between bringing one tool or another to bear simply by tilting the head.

Steel fishing trace might be a useful material for the cord.

Oh, and keep looking at the Stewart platform, and also "Crank" variants which require fewer multi-directional joints. I reckoned they were vey nice but waaay to complicated for the initial attempts. Also quite expensive - 6 stepper motors...

Vik :v)

Oh, and keep looking at the Stewart platform, and also "Crank" variants which require fewer multi-directional joints. I reckoned they were vey nice but waaay to complicated for the initial attempts. Also quite expensive - 6 stepper motors...

Vik :v)

All good suggestions, and some good leads for research. I'll be delving into feasibility once i get the rig up and runnning and will let you know what i come up with...

Some places to browse: music shops, bait and tackle shops, sporting goods stores, art supply shops. Never know what you might find.

Chandlers are good sources of interesting bits, mostly available in stainless materials and fairly standardised. You'd be surprised how many bits of rigging NASA use in their endeavours!

Vik :v)

Post a Comment

Vik :v)

<< Home