Tuesday, February 17, 2009

Back From Madrid

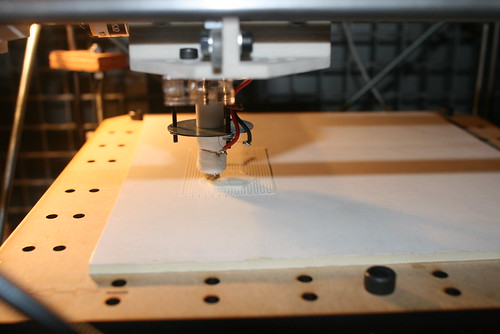

Whew! I'm back from Interactivos '09 in Madrid where I was leading the project to build a reprap machine. It was a really fun, really intense 2 week project where we built an entire, functioning RepRap machine from scratch (well, sort of... we used PCBs and printed parts)

Whew! I'm back from Interactivos '09 in Madrid where I was leading the project to build a reprap machine. It was a really fun, really intense 2 week project where we built an entire, functioning RepRap machine from scratch (well, sort of... we used PCBs and printed parts)I'd like to give a big thanks to the whole Medialab Prado crew. They are really some awesome people over there doing some really rad things. They made me not ever want to leave Madrid. The city and people and culture they have there are really something to be proud of. It sort of makes my hometown of NYC seem a bit backwards. ;)

Here's a quick brain dump:

* tornillas = bolts

* tuercas = nuts

* canas = hangover ;)

* tapas = awesome :)

RepRap machines *can* be built from parts made on a Z Corp machine, but its tough and you have to be careful. We broke some parts and had to hack together some replacements.

It was really cool to use the machine to print out parts to fix itself and thus improve build quality. We broke the Z motor coupling and cobbled a fix together with hose clamps and heat shrink tubing. The Z axis had some major wobble. One of the first parts we printed was a replacement Z motor coupling from ABS. we put it on and the wobble improved dramatically. Yay for self-replication!

I learned how to do 3d modeling (gasp! yes, i dont know how to... this project is so fricking huge!!!) I learned about Sketchup, Blender, and how to make the two play nicely (blog post coming soon)

Edit: I also learned a really cool technique for doing embossed lettering on printed parts. Blog post coming soon.

Anyway, big shouts to my collaborators: Catarina, Ricardo, Guillermo, Kirsty, Erica, Christine, Juan, and everyone else who stopped by to pitch in that I have forgotten.

Cheers,

Zach

Comments:

<< Home

Brilliant Zach! I was a little nervous about the strength of the Z-Corp parts when I left, and you've shown I was too pessimistic.

Did you by any chance keep (or keep a list of) the bits that broke? Given that Z-corp parts are always weak those will probably be the weakest bits in general for other processes too, and so it might be an idea to concentrate on them for some strengthening re-designing.

Did you by any chance keep (or keep a list of) the bits that broke? Given that Z-corp parts are always weak those will probably be the weakest bits in general for other processes too, and so it might be an idea to concentrate on them for some strengthening re-designing.

umm... just about everything that was structural ;)

in list of importance / fragility (maybe):

* motor couplings (completely broke)

* z bed constraints (break under stress)

* opto endstop mounts (no way in hell)

* x idler housing (cracked, but okay)

* corner brackets (broke, but we patched with epoxy putty)

* belt clamps (easy to hack up)

we were very gentle and still managed to break some. the ABS parts are super strong and we replaced most of the parts with it before i left

in list of importance / fragility (maybe):

* motor couplings (completely broke)

* z bed constraints (break under stress)

* opto endstop mounts (no way in hell)

* x idler housing (cracked, but okay)

* corner brackets (broke, but we patched with epoxy putty)

* belt clamps (easy to hack up)

we were very gentle and still managed to break some. the ABS parts are super strong and we replaced most of the parts with it before i left

unfortunately i was not to good with the camera. its funny how some things seem less important when you're on a tight deadline.

there are some pics floating around the net though:

http://flickr.com/photos/medialab-prado/3252738629/in/set-72157612999072617/

http://flickr.com/photos/medialab-prado/3270981647/

http://flickr.com/photos/medialab-prado/3271795454/

there are some pics floating around the net though:

http://flickr.com/photos/medialab-prado/3252738629/in/set-72157612999072617/

http://flickr.com/photos/medialab-prado/3270981647/

http://flickr.com/photos/medialab-prado/3271795454/

Hey, welcome back! Glad you and Dr Bowyer got a chance to work together in person on this one, too - and looks like we might have a standardized pinch-wheel extruder coming soon as a result! Great! :D

Got my parts just fine while you were gone too, so your store was in good hands (but you probably already knew that ;)

Got my parts just fine while you were gone too, so your store was in good hands (but you probably already knew that ;)

Hay gente interesada en Tenerife (Canary Islands). Por favor contactar con imagina punto canarias arroba gmail punto com. O, mejor todavía, http://www.imagina-canarias.org/foro/viewtopic.php?f=7&t=13

ENGLISH: There's folks interested in reprap in Tenerife (Canary Islands). Please contact imagina dot canarias at gmail. Or better still http://www.imagina-canarias.org/foro/viewtopic.php?f=7&t=13

GRACIAS/THANKS!

Post a Comment

ENGLISH: There's folks interested in reprap in Tenerife (Canary Islands). Please contact imagina dot canarias at gmail. Or better still http://www.imagina-canarias.org/foro/viewtopic.php?f=7&t=13

GRACIAS/THANKS!

<< Home