Saturday, February 05, 2011

Thermocouple vs Thermistor

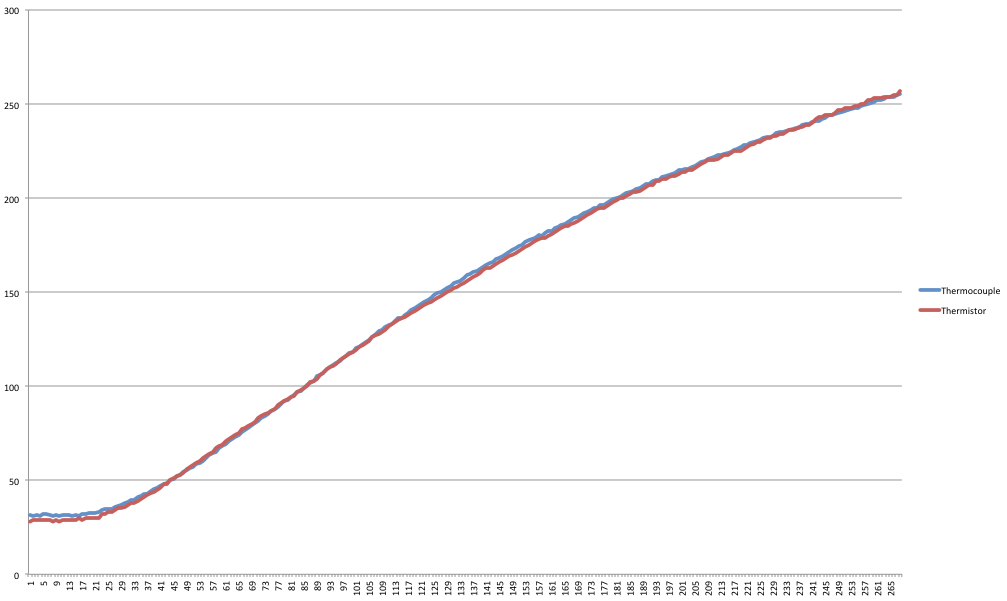

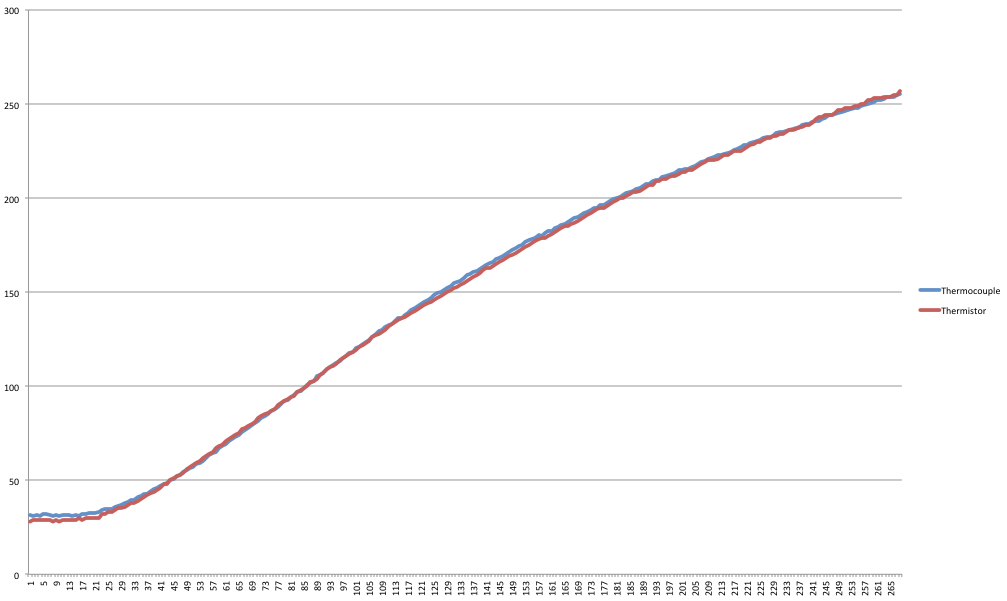

I originally wanted to just calibrate the thermistor table I used in my FW, since I remember that Camiel from Mendel-parts was moaning that his table was horrible and it affected his prints, I now just guess that his table wasn't made for his thermistor. I used one generated exactly for my thermistor by createTemperatureLookup.py from SVN. So I crated fake heater with both Thermocouple and Thermistor and written small sketch in Arduino to generate table, BUT I did want first to simply try how imprecise it is. Then I was shocked, both readings were pretty close, actually biggest deviation was 3°C. You can see the graphs under and also download the Arduino sketch and sample data.

My verdict, is that both technologies are good for heaters and heatbeds, the precision is mainly affected by mounting on heater. Also be careful to use precision resistors for thermistor circuits, thats all :-)

Code and data can be downloaded on RepRap wiki.

My verdict, is that both technologies are good for heaters and heatbeds, the precision is mainly affected by mounting on heater. Also be careful to use precision resistors for thermistor circuits, thats all :-)

Code and data can be downloaded on RepRap wiki.

Comments:

<< Home

Yes I calibrate each thermistor with thermocouple and find they track within 2 or 3 degrees after that. I don't use the values off the datasheet. I take readings at room temp and 240C and work out beta.

Nice experiment! Thermistors are a lot cheaper than thermocouples and need less complicated hardware so I like the outcome. But, isn't the dynamic response of the type of sensor more important than the largest error. Particularly since you are going to use it in a closed loop controlled application. In that case you would want to know how fast the sensor responds to temperature changes around 220-240°C. Maybe it's this property that will show more difference between different types of sensor.

Thercouples are more inline for the temperature measurement for the extruder hot end, thermistors are designed only for up to 150 degrees continuous, or a really good one, 200 degrees continous.

I wish you wouldn't keep posting this un-truth. The Epcos glass bead thermistors we use are rated for 300C continuous and I have yet to have one fail, apart from the leads snapping off.

I think thermistors are great for their price tag. You can definitely do without a thermocouple.

We're putting a thermocouple in the Ultimaker because you cannot really damage them or mishandle them. Thermistors require some more skill.

We're putting a thermocouple in the Ultimaker because you cannot really damage them or mishandle them. Thermistors require some more skill.

Hm.. I think i misshandled my termocouple (shortcut to ground) and by this burned my makerbot mainboard..

Now i sugest replace with a Rumba board. And want to cut the termocouple and place a thermistor there. Just to use the nice thermocouple wire. Will this work or will it affect the thermistor reading?

Now i sugest replace with a Rumba board. And want to cut the termocouple and place a thermistor there. Just to use the nice thermocouple wire. Will this work or will it affect the thermistor reading?

It will affect the reading because thermocouple wires have significant resistance. I measured one at 13 Ohm. At 240C a 100K thermistor has a resistance of only 266 Ohm, so that would give a 5% error.

Also the junctions you make with the thermocouple wires will be thermocouples, so depending on how hot they get they will add a voltage offset as well.

Post a Comment

Also the junctions you make with the thermocouple wires will be thermocouples, so depending on how hot they get they will add a voltage offset as well.

<< Home