Monday, January 16, 2006

Fourth Round Dieting...

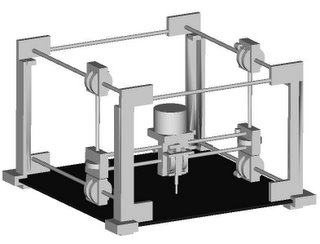

I shifted the design over to DC encoded motors from steppers from standard steppers. I also fixed the threaded rods and made them do double duty as structural members. This entailed moving the motors out onto the moving platforms, a move that will require some bit of coiled power cord which wasn't required before.

Please note that cross-bracing isn't shown.

The net result was that the design shed nearly 22 kg of expensive steel rods and several kilograms of polymer.

The quantity survey takeoff on the design is now...

Polymer - 9.5 kg

Steel - 10.3 kg

Glass - 21 kg

The design specifies 16 mm threaded steel rods. It is possible that smaller diameter rods may work or that we can thread tubing. Losing half of the rods mass out of the middle of the cross section would lower the rod's strength only about 10% if memory serves.

Comments:

<< Home

I still rate Meccano, thoguh the electronics of the new Lego look very interesting.

Why Meccano? Because the whole thing is built on a 12.5mm grid of 4mm holes, and that's very easy to fabricate a part for. Meccano is also very, very rigid, and can support a weight of several kilos if necessary.

But whatever gets the job done, basically. We're now at a point where we can get a stepper motor moving and a nozzle extruding fairly easily. The components for our kit are starting to come together and we may well have progressed beyone the Lego stage of prototyping.

As soon as the Mk 1 "Darwin" release is out, we'll be able to use RepRaps to make the new bits :)

Vik :v)

Why Meccano? Because the whole thing is built on a 12.5mm grid of 4mm holes, and that's very easy to fabricate a part for. Meccano is also very, very rigid, and can support a weight of several kilos if necessary.

But whatever gets the job done, basically. We're now at a point where we can get a stepper motor moving and a nozzle extruding fairly easily. The components for our kit are starting to come together and we may well have progressed beyone the Lego stage of prototyping.

As soon as the Mk 1 "Darwin" release is out, we'll be able to use RepRaps to make the new bits :)

Vik :v)

Meccano is actually Imperial - holes are 5/32", spacing 1/2". The screws are 5/32" British Standard Whitworth.

I have seen at least one Meccano ripoff that was metric, however - M4 bolts, I forget the hole spacing. It wasn't very good.

Post a Comment

I have seen at least one Meccano ripoff that was metric, however - M4 bolts, I forget the hole spacing. It wasn't very good.

<< Home