So to very briefly summarise, with the use of bearings the wedge attracts a higher proportion of fasteners. I consider this a small price to pay for much smoother running. The volume of RP parts is the same, as is the area of sheet used in the construction, however the number of structural components is significantly reduced. The assembly has been simplified using only a third the number of different bolt types, and the total assembly volume has halved whilst maintaining a similar build volume.

Here's an analysis of the RP parts in the Wedge design (nod to Forrest for the suggestion). Clearly we could save some volume by optimising the vertices etc etc

great numbers, i think wedge/mendel will be my first reprap machine :-D

ReplyDeletethanks for your works

Great numbers! Thanks, eD!

ReplyDeleteVery nice!

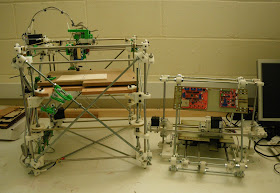

ReplyDeleteDarwin looks intimidating when compared to the wedge.

I'm excited! :D

i am thinking i will be building a mendle too, i am still trying to figure out how i will build it though. i do not know anyone that can print out the parts for me so i think mine will be more of a repstrap mendle.

ReplyDeletei am looking forward to seeing what people will do with this more and more.

Here, at bath uni, a job we're working on is to sprout more wedges for the lab to culminate as a mini factory to kick out parts. It will be small volume, but we might be able to start trickling sets out soon... don't ask about orders just yet though, it's a few months away from that.

ReplyDeletethats good to see, once you get a few running i don't think it takes too long to print them out. i hope i can build one in the next few months.

ReplyDeletei dont know of any one else in my part of sask that wants to build one,

If the design calls for roller bearings why have you chosen a circular cross section for the supports (price accuracy?) a square one would be 2x as stiff

ReplyDeleteHow can the wedge possibly use over 600 washers?? Is one of the rods made of a wire stretched inside a solid stack of washers? That's a crazy amount.

ReplyDeleteEvolution at work. Looking forward for more benefitial mutations!

ReplyDeleteHmmmm I wonder if printed washers could be substituted.........

ReplyDeleteif you are going to sell kits for mendel, I'm interested!

ReplyDeleteDoes anyone have a full CAD file for Mendel that I can play with please. Looking at providing Metal parts at really cheap prices for initial Repstrap machine. Other than this could anyone provide me with a set of printed parts. Bristol, UK. Great work, I'd like to get involved.

ReplyDeleteHi All is there any way so as to increase the surface fininsh like if we can decrease the print reslution and noozel so that we can print fine jewellery models?

ReplyDeletei am seriusly interested

please if any one can find a solution will be very helpful