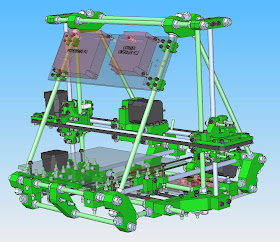

Vik’s already introduced it below and is working hard on a prototype as we speak, but I thought I’d chuck out a few tasty details. Those with a Darwin may appreciate some of the latest specs:

- The footprint is 420 mm x 420 mm, with a cantilevered x-axis of length 512 mm. Height is 345 mm.

- Print area is currently 160 mm x 220 mm. This could be improved to 200 mm x 220 mm with the use of the Bowden extruder (which could rely on a smaller carriage)

- Print height will be ~ 160 mm.

- Assembly requires only 3 different bolt sizes (M4 x 40, M4 x 16 and M3 x 20).

- Axes run on bearings (624s and 608s). The beauty of the wedge configuration is that axes are not over-constrained… this means that all axes can be easily powered with NEMA 14 motors. Motor brackets are also compatible for NEMA 17s.

- Top gantry available for tool-head changer

We’re building a prototype in our lab as well. I’ve had a lot of requests for documentation – this will follow in good time. It’s one thing to knock up something that works… but getting things user-friendly for the rest of the world is a different kettle of fish entirely. I should say that the RepRap lab here at Bath University is working flat out to get it out asap, so your patience would be greatly appreciated over the next few months ;-)

Meanwhile here’s a VRML of the general assembly so far to get your teeth stuck into.

Its looking real good now.

ReplyDeleteThanks for the VRML, i've been looking at the old VRML off of Adrian's site.

One thing that I m concerned about is the number of pulleys that we will have to make, from looking at the model, are there just 3 sizes?

The y-idler-bracket_1off.stl as an example doesn't show the ability to tension the belt, are you guys planning on a feature to help in tensioning the belts?

i was wondering how dose this setup deal with vibrations and wobbling when it is printing near the top.?

ReplyDeletei do like this idea i think this is the one i will start to build here soon

Ed:

ReplyDeleteApproximately how much torque will be proved necessary to function properly ?

So what's the volume of the printed parts and how long does it take you to print a set?

ReplyDeleteFantastic work chaps.

ReplyDeleteIt looks like the team are working super-hard!

well done.

> One thing that I m concerned about is the number of pulleys that we will have to make, from looking at the model, are there just 3 sizes?

ReplyDeleteNo puleys, just bearings

> i was wondering how dose this setup deal with vibrations and wobbling when it is printing near the top.?

Don't know yet. Early tests suggest it'll be OK.

> Approximately how much torque will be proved necessary to function properly ?

The NEMA 14s we tested had holding torque of 1400 g.cm

> So what's the volume of the printed parts and how long does it take you to print a set?

Good question, something we should know soon

> The y-idler-bracket_1off.stl as an example doesn't show the ability to tension the belt, are you guys planning on a feature to help in tensioning the belts?

ReplyDeleteTensioners are not necessary (at this load) for ended belts - tension can be set at the terminating clamps.

Tensioners are only really required for endless belts... in this case the z transmission. We have an adjustable pulley in place for this.

Is there a way I can get the model in any other format besides vrml? I'd love to start playing with it as I'm about to have access to a makerbot, and my distro is giving me fits over the vrml file.

ReplyDeleteCheers! (Sorry if there is some totally obvious place to get the files I haven't found yet, I'm new here)

Ed,

ReplyDeleteInteresting work, but I'm somewhat concerned about a possible under-constraint of the mechanism.

You wrote:

The beauty of the wedge configuration is that axes are not over-constrained…

[For my descr, let X be the bottom table's DOF, Y be the other horizontal DOP, and Z be vertical.]

Consider the vertical stage, which is supported on two smooth vertical rods, by four pairs of bearings riding on each rod. Each such foursome constrains the motion (of their center) to move only in Z, but individually do not prevent rotation about the axis of their guide rod. Incremental rotation (of the Y stage assembly) about the vertical axis of the left guide rod *is* opposed by the bearings on the right side, because that rotation would cause the right-side bearings to interfere with their guide rod. However, the situation does not appear symmetical to me. Now consider an incremental rotation about the right-side's guide rod. The resultant motion of such a rotation does not appear to be opposed by the bearings on left-side guide rod. (If fact, it appears to be perpendicular to the direction those bearings constrain.) As a result, I don't see what bearings prevent the second rotation I have described (or al least attempted to.)

Let me try another way of wording my concern: With the frame fixed, if I were to grab the right side of the vertical stage, and push that side of it (while letting the left-hand side alone) in either the +X or -X direction, what bearings would prevent that side of the vertical stage from moving in X? I don't think the bearings on the opposite vertical rod would prevent this; I think those bearings would instead rotate around their guide rod to accomodate the motion.

It may well be that I'm missing something about the bearings and the constraints they oppose, and I would be grateful for any comments.

Thanks,

Larry

> Is there a way I can get the model in any other format besides vrml?

ReplyDeleteSTLs and model files will part of our release

> possible under-constraint of the mechanism.

Take the x-axis which is allowed to move in Z. Left bracket constrains at two points on the Z-bar, 3 bearings at each point, constraining pitch and roll but not yaw (rotation in the XY plane). Right bracket simply prevents yaw [in theory this is only required at one point, not two, however the concept is over-engineered to allow for the possibility of torsion generated from potentioal subtractive milling heads) This makes the constraint perfect. Principle is applied in X Y and Z.

Ed,

ReplyDeleteYour recent post of a photo of the Wedge prototype, next to your Darwin makes the bearing situation much clearer; thanks much. In particular, the trio of bearings arranged around the left vertical rod wasn't apparent to me until I saw this photo.

-- Larry