Sebastien mailed me a couple of kilos of polyethylene glycol. This is a water-soluble wax-like polymer that melts around 70oC. We have been thinking of using it as a support material.

I've been playing with it, and on its own it's much too fluid when molten - it has a viscosity similar to water. It thickens as it cools, but in order to get an extruded filament that way one would need far too fine a temperature control.

So I melted some and mixed it (2:3 by weight) with icing sugar. That makes a paste which is the ideal consistency. And it sets to a material that is like candle wax, but is water soluble (because both the sugar and the polyethylene glycol are).

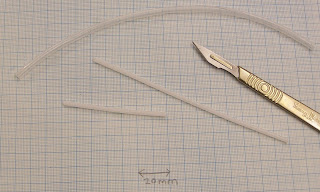

I used the same trick as I used the other day to make a 3mm rod of Wood's metal - squirting it from a syringe down a 3mm silicone tube, letting it freeze, then splitting that off with a scalpel. It's a bit brittle (as you can see its broken in two). This is good for support material removal, but for other tasks it would help if it was more flexible.

I tried miking it with glycerin as a plasticiser (medically, polyethylene glycol is often mixed with glycerin), but it seemed to react with the sugar to curdle and form lumps. This itself was interesting, but not quite what I wanted. so I'll see if I can find another compound that will make it more pliable. If I can do that it will definitely go through the standard extruder.

Would a small quantity of CAPA make it more pliable? Dunno if it's sufficiently miscible or not.

ReplyDeleteI think this is what CAPA is used for in the plastics moulding industry.

Vik :v)

CAPA and PEG are most likely not miscible, due to the physics of long-chain interactions. Basically, high molecular weights mean that the (temperature * entropy of mixing) is almost negligible compared to the enthalpy of mixing. I've heard that the polyester in Coke bottles and the polyester in Pepsi bottles aren't miscible.

ReplyDeletePEO, on the other hand, should mix with PEG just fine...because they are chemically identical. (I know, odd naming convention, eh?)

PEO has a much higher molecular weight than PEG, which will help with both strength and liquid viscosity.

You might be able to get a CAPA/PEO emulsifier by finding a way to transesterify some CAPA oligomers onto the ends of the PEG, similar to making soap or biodiesel. That is to say, if they don't mix as-is, try heating a small amount with lye & water, and see if the result lets you mix a larger batch.

thanks for dropping the knowledge there joel... it sounds like you really know your stuff.

ReplyDeletehowever, i think that we need a support filler that is as easy as possible to make. ideally its something we could just plug and play like polyfilla or PEG + (sugar|salt|four)

btw... whatever happened to polyfilla?

also, have you tried mixing flour with the PEG instead of sugar? i know that flour works really well for providing stability to stuff and making it sturdier.

Salt is interesting - it may well be worth trying. I went for icing sugar because it's readily available in a very fine powder.

ReplyDeleteThe CAPA experiment is simple to try, so I will; I'll also see if I can get some PEO. I might also just try soap...

Can anyone shed any chemical light on the reaction with glycerin?

I hadn't thought of flour; I'll try that too. Polyfilla is still going; but the advantage of this is its solubility and the possibility of using the standard extruder.

ReplyDeleteI'm going with the local equivalent of Pollyfilla (spackling compound), myself. I can buy it in buckets at the hardware store premixed and ready to spoon into a balloon, condom, toothpaste tube or whatever.

ReplyDeleteHow about trying some gelatin or pectin for your plasticizer? I'm thinking of those "gummy worms" here. They've got a very rubbery texture and are definitely water soluble so should mix with PEG.

ReplyDeleteah yes... you can get powdered gelatin that might work really well.

ReplyDeleteSebastien has come up trumps again, with this reference:

ReplyDeletehttp://meetings.aps.org/Meeting/MAR05/Event/23997

So I bought some citric acid from the chemist ("Ah! Making lemonade sir?").

I melted 5g of PEG and repeatedly added 0.25g of citric acid (which dissolved in the melt easily) and put a few drops on a microscope slide at each stage.

The more citric acid you have, the slower it solidifies, but it always does. The sample with a ratio of 5:0.75

PEG:CA was the first that is not brittle.

Next I'll mix some at that ratio with the icing sugar to see if I can make a paste that doesn't fracture when it sets.

Yup - that works. 12g PEG + 2g citric acid (melt and dissolve) then + 18 g icing sugar produces something that, when molten (65 C) is a paste that holds its form but that will extrude easily.

ReplyDeleteI put it down a 3mm silicone tube with a syringe, and split the tube with a scalpel to make a 3mm rod. It's flexible, and should go in the standard estruder.

I'm glad I'm not the only one who spells extruder with an "s".

ReplyDeleteIs PEG edible? That sounds like a sweet-tart: Sugar, Citric acid and PEG. You could just lick the support structure off!

ReplyDeleteIt's nearly edible. It's an ingredient in Dr Pepper, is added to very personal lubricants, and is used as a cure for constipation.

ReplyDeleteVik :v)

"It's flexible, and should go in the standard estruder."

ReplyDeleteOr not. I've tried it, and the material isn't strong enough to withstand the rotating screw drive, which just strips it away. I also tried cornflour instead of icing sugar, which also makes a good paste. Still not strong enough though.

Still got that old pinch-wheel design kicking around?

ReplyDeleteVik :v)

Drat. I had my hopes up. Maybe it will work with the pinchwheel.

ReplyDeleteI emailed Dr. Barone with a few questions. He wasn't sure that it would work, and suggested we try PVA.

Note on nomenclature (which I was fuzzy on, until now):

(All via wikipedia)

The solid, sold as granules by industrial adhesive suppliers, is

Polyvinyl acetate

http://en.wikipedia.org/wiki/Polyvinyl_acetate

The liquid emulsion, sold in bottles as wood glue, is

Polyvinyl alcohol. You get polyvinyl alchol by hydrolysis of polyvinyl acetate. ("Hydrolysis is a chemical reaction or process in which a chemical compound reacts with water.") In this case adding water makes the acetate groups come off, and the polyvinyl acetate becomes polyvinyl alchol. Adding _more_ water turns the polymer into a suspension of polymer in water, aka wood glue.

http://en.wikipedia.org/wiki/Polyvinyl_alcohol

Apparently polyvinyl alcohol is used in the building trade as a dry fiber to add to concrete. This may be a cheap way to source it.

http://www.drymix.info/industry-directory/fiber/