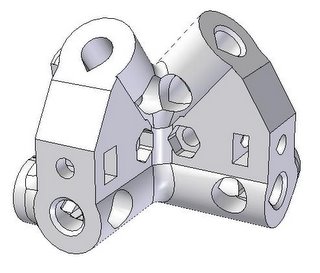

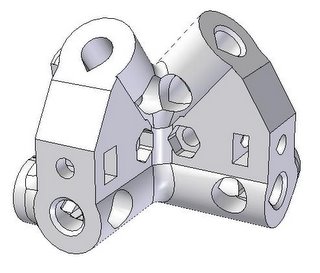

This is not news... but when I designed the trickiest most complex component I've done in a while...

and then come back after the weekend to find EIGHT real life versions of them waiting for me in the bed of the RP machine...

... I think "think this is the best manufacturing technology in the world. Everybody should have one." (Hang on, that kinda what we're...)

Looks beautiful! :-)

ReplyDeleteJust wait til some of us crazy artist-designer types get our mits on this stuff.

ReplyDeleteOne of the things I want to do is simulate bird bones; specifically the inside. Can't tool that geometry for production.

Oh, at least one crazy artist-designer type already has :)

ReplyDeleteEd, are you FDMing the pulleys too?

Vik :v)

Man! you should be able to feel the envy radiating off me even across the globe.

ReplyDelete> Ed, are you FDMing the pulleys too?

ReplyDeleteYup! Trying to keep that "and everything apart from the motor, bars, string and bolts is RP" sentence alive for later...

Ahem! Ed is too modest to say this, but when he graduated in 2005 he was one of the top three mechanical engineering students in the U.K., as he was on the 3-person shortlist for the annual SET awards.

ReplyDeleteI mention this here, because he says there are eight parts in the picture and a count fails to confirm this.

Counting is one of the skills we staff more or less take for granted in graduates with First Class Honours from Bath...

You mean he hasn't done some cunning tesselation and stacking to conserve plastic? :)

ReplyDeleteWell done Ed!

Vik :v)

***Ahem! Ed is too modest to say this, but when he graduated in 2005 he was one of the top three mechanical engineering students in the U.K., as he was on the 3-person shortlist for the annual SET awards.***

ReplyDelete...and he wanted to do advanced work with you. If I were in your shoes I'd be so proud that I'd be impossible to live with. :-D

> I mention this here, because he says there are eight parts in the picture and a count fails to confirm this.

ReplyDeleteWhat can I say, I learn from the best ;)))